خط إنتاج روبوت خزان الغاز

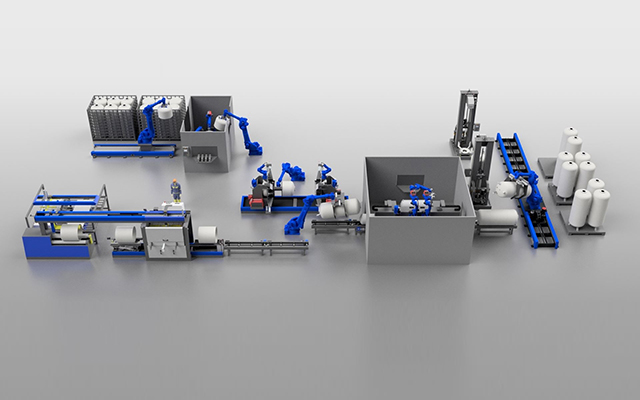

The production line for gas tank robots is a highly sophisticated and meticulously designed system that integrates advanced robotics, automation, and precision engineering to manufacture robotic systems specifically designed for handling and inspecting gas tanks. This production line is a testament to modern manufacturing capabilities, ensuring efficiency, accuracy, and safety throughout the entire process.The production process begins with the design and prototyping phase, where engineers utilize cutting-edge CAD (Computer-Aided Design) software to create detailed blueprints of the gas tank robots. These designs are optimized for functionality, durability, and ease of maintenance. Once the design is finalized, the production line transitions to the fabrication stage. Here, high-precision CNC (Computer Numerical Control) machines are employed to manufacture the robot's structural components, ensuring that each part meets stringent quality standards.The assembly phase is where the production line truly showcases its automation prowess. Robotic arms, guided by advanced AI algorithms, meticulously assemble the various components of the gas tank robot. These robots are equipped with sensors and cameras to ensure precise alignment and correct installation of each part. The assembly process is closely monitored by quality control systems that detect and rectify any deviations from the design specifications.After assembly, the gas tank robots undergo rigorous testing and calibration. This phase involves simulating real-world conditions to ensure that the robots can handle gas tanks safely and efficiently. The testing process includes checking the robot's mobility, grip strength, sensor accuracy, and overall performance. Any issues identified during testing are addressed promptly to ensure that the final product meets the highest standards of reliability and safety.The production line also incorporates advanced logistics systems to manage the flow of materials and components. Automated guided vehicles (AGVs) transport parts between different stages of the production process, minimizing human intervention and reducing the risk of errors. Additionally, the production line is equipped with real-time monitoring systems that track the progress of each robot through the manufacturing process, providing valuable data for continuous improvement.Safety is a paramount concern in the production of gas tank robots. The production line is designed with multiple safety features, including emergency stop mechanisms, protective barriers, and advanced sensors that detect and prevent potential hazards. Workers are provided with comprehensive training to operate the equipment safely and effectively.In conclusion, the production line for gas tank robots is a marvel of modern engineering, combining advanced robotics, automation, and precision manufacturing to create highly reliable and efficient robotic systems. This production line not only ensures the highest quality standards but also prioritizes safety and sustainability, making it a benchmark in the field of industrial automation.

نتاج

تصنيف:

خط إنتاج روبوت خزان الغاز

-

خط إنتاج روبوت خزان الغاز

تصنيفها: خط إنتاج روبوت خزان الغازالمشاهدات: 78عدد:وقت الإصدار: 2025-09-08 11:21:33أخط إنتاج روبوت خزان الغازهو نظام تصنيع آلي متخصص للغاية مصمم لإنتاج مجموعة واسعة من أوعية الضغط، بما في ذلك أسطوانات غاز البترول المسال، وخزانات البروبان، وحاويات الغاز الطبيعي، وصهاريج التخزين الصناعية، وأسطوانات الغاز المنزلية. تُستخدم هذه الخزانات على نطاق واسع في الطهي السكني، والتدفئة، وإمدادات الوقود الصناعي، والمعالجة الكيميائية، وتخزين الطاقة.اعتمدت الطرق التقليدية لإنتاج خزانات الغاز بشكل كبير على اللحام اليدوي والقطع والفحص، والتي كانت عرضة لعدم الاتساق والأخطاء البشرية ومخاطر السلامة. مع تزايد الطلب العالمي على تخزين الغاز الموثوق والآمن، يتجه المصنعون بشكل متزايد إلى الأتمتة. بالد...

أخبار

تصنيف:

لا توجد نتائج بحث!

حالة

تصنيف:

فيديو

تصنيف:

لا توجد نتائج بحث!

تحميل

تصنيف:

لا توجد نتائج بحث!

تجنيد

تصنيف:

لا توجد نتائج بحث!

المنتجات الموصى بها

لا توجد نتائج بحث!

واتس اب

واتس اب هاتف

هاتف